Electrical Bus Duct Experts

Isophase, Non-Segregated, Segregated, Cable

As the world's leading power plant maintenance service provider and life extender of metal enclosed electric bus duct systems, EBI focuses on critical electrical asset life extension. Their turnkey bus duct maintenance, repair, equipment enhancements, custom fabrication, and transformer change-out support solutions enable power plants to extend the lifespan of their system critical electrical assets and improve overall plant performance and safety.

Our Core Competencies Include:

Isolated Phase Bus Duct (IPB):

- Fleet System Assessment & Planning

- Installation & Replacement

- Repairs & Refurbishment

- Rebuild & Fabrication (any OEM)

- Retrofits & Modifications

- Transformer Change-Outs

- Offline Bus Duct Maintenance & Inspection

- Cryogenic Cleaning

- Offline Robotic Video & Borescope Inspection

- Online Continuous Monitoring Solutions

- Noninvasive System Diagnostics & Troubleshooting

- Aftermarket System Enhancements

- Dry Air Systems

Non-Segregated Bus Duct:

- Fleet System Assessment & Planning

- Installation & Replacement

- Repairs & Refurbishment

- Rebuild & Fabrication (any OEM)

- Retrofits & Modifications

- Transformer Change-Outs

- Offline Bus Duct Maintenance & Inspection

- Online Continuous Monitoring Solutions

- Noninvasive System Diagnostics & Troubleshooting

- Aftermarket System Enhancements

- Heaters

Segregated Bus Duct:

- Fleet System Assessment & Planning

- Installation & Replacement

- Repairs & Refurbishment

- Rebuild & Fabrication (any OEM)

- Retrofits & Modifications

- Transformer Change-Outs

- Offline Bus Duct Maintenance & Inspection

- Online Continuous Monitoring Solutions

- Noninvasive System Diagnostics & Troubleshooting

- Aftermarket System Enhancements

- Heaters

Cable Bus Duct:

- Installation & Replacement

- Cable Tray Installation & Modification

- Testing & Terminating

- Support Steel Installation & Modification

- Repairs & Troubleshooting

- Project Management

- FE/Planners

Downloads

Related Projects

Experience a Failure?

24/7/365 Emergency Services

Asset Life Extension

Bus Duct Maintenance

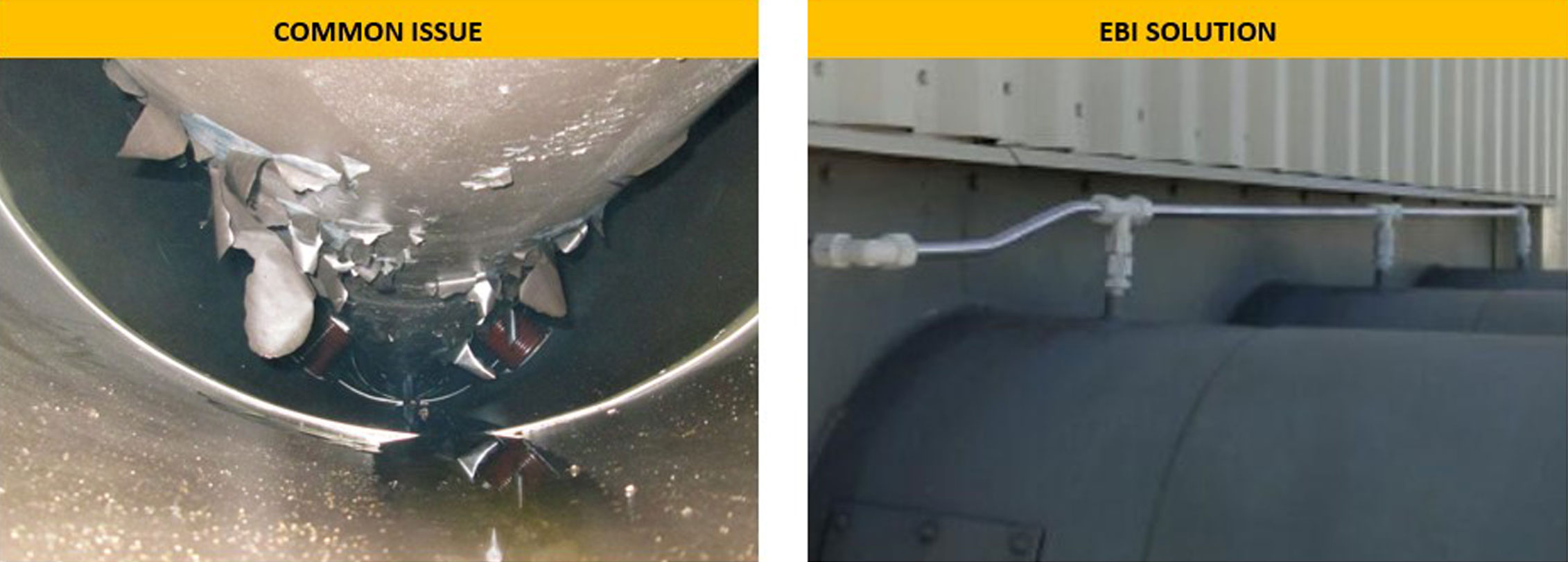

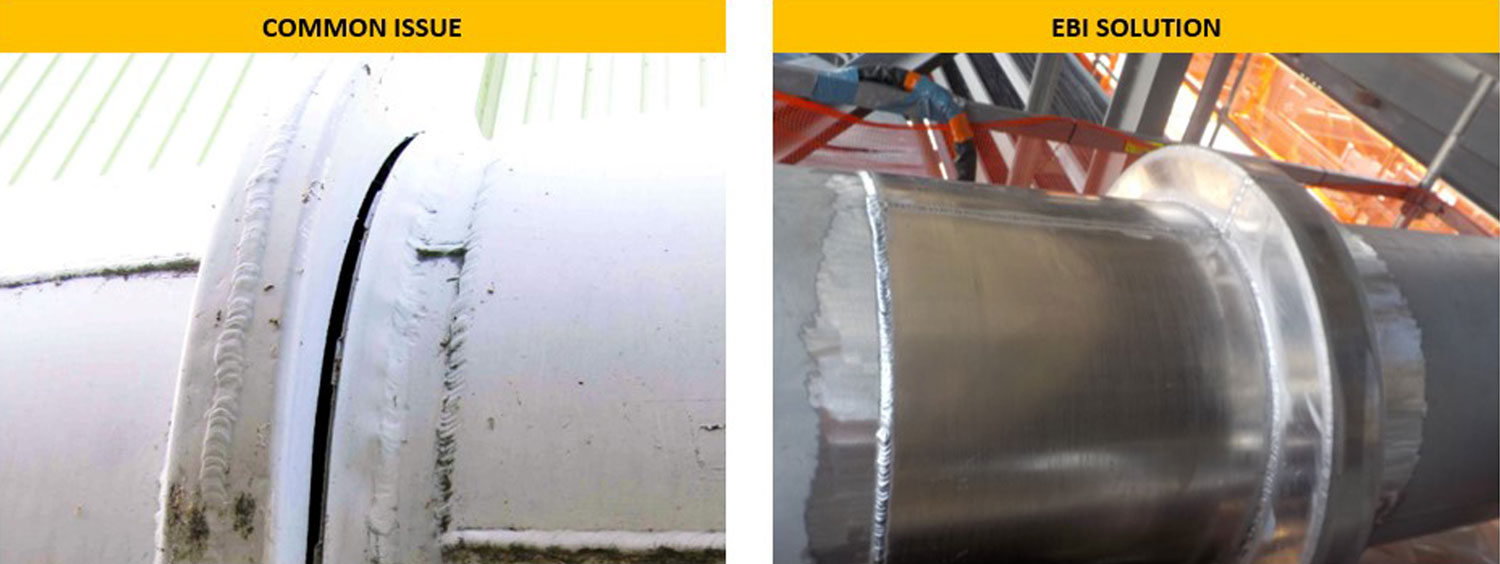

Despite the fact that bus duct systems are critical to producing power, many plant asset managers and personnel overlook the importance of the system because it has no moving parts. However, these critical components are stand-alone, non-redundant, and customized to each plant. When a bus duct fails, the entire power generation unit is shut down. The unplanned downtime results in significant revenue loss and emergency repair costs.

EBI’s long-standing history of servicing and refurbishing these components has shown that these costly bus duct failures can easily be avoided with routine and consistent inspection and maintenance performed by their highly qualified and experienced bus duct experts.

Most OEMs recommend electrical bus duct maintenance yearly, at every scheduled shut-down, or at a minimum of every 24 months.

Proactive utilities are implementing fleet wide critical asset initiatives by partnering with EBI, the industry leading bus duct service experts, who can properly document and correct potential issues before they materialize; resulting in less downtime and increased operational efficiency and safety.

Common System Issues:

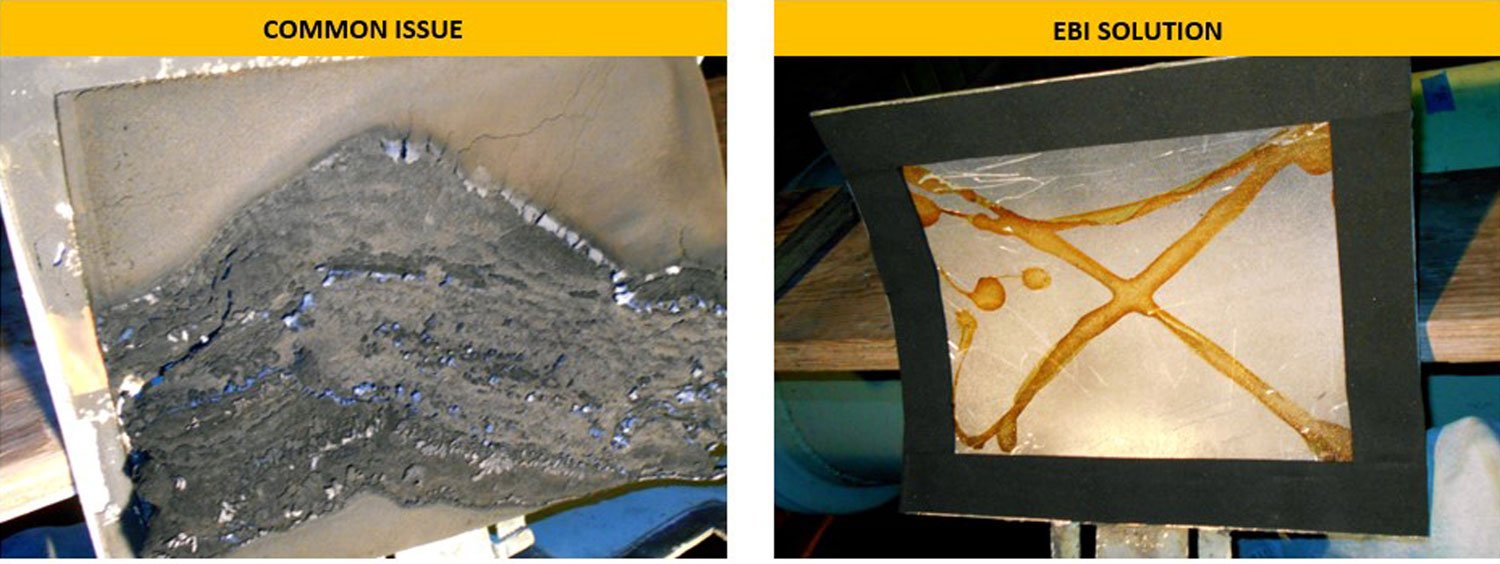

- Presence of moisture or water intrusion

- Dirt and debris build-up

- Grounding issues

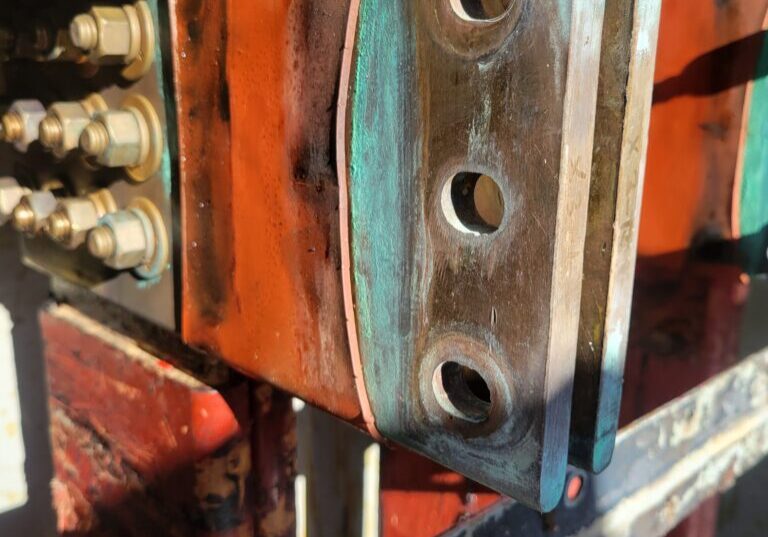

- Improper, loose, or missing hardware

- Damaged flexes, laminates, and jumpers

- Inadequate or cracked welds and/or bellows

- Warped surfaces or lack of silver plating

- Excessive heating

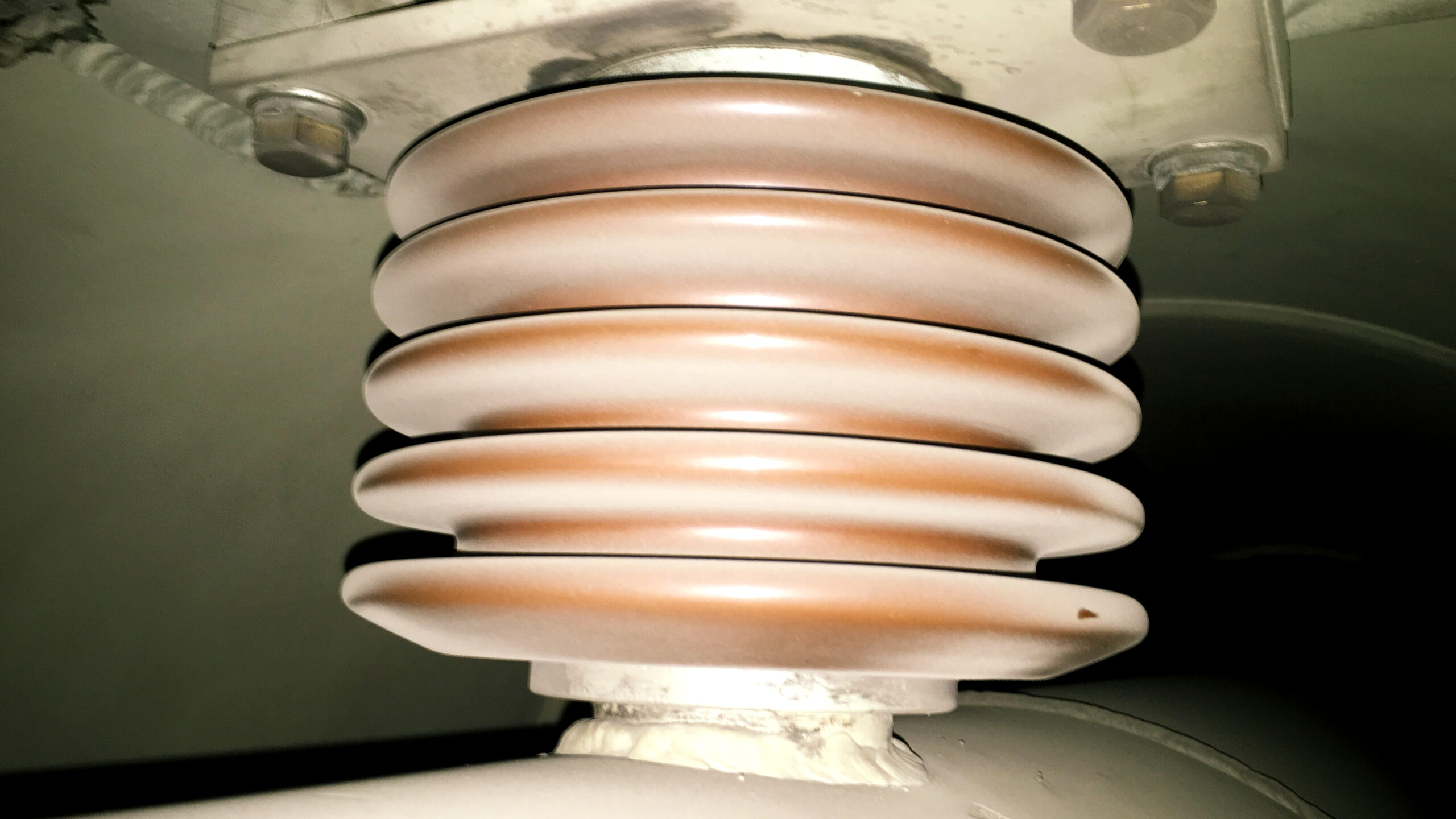

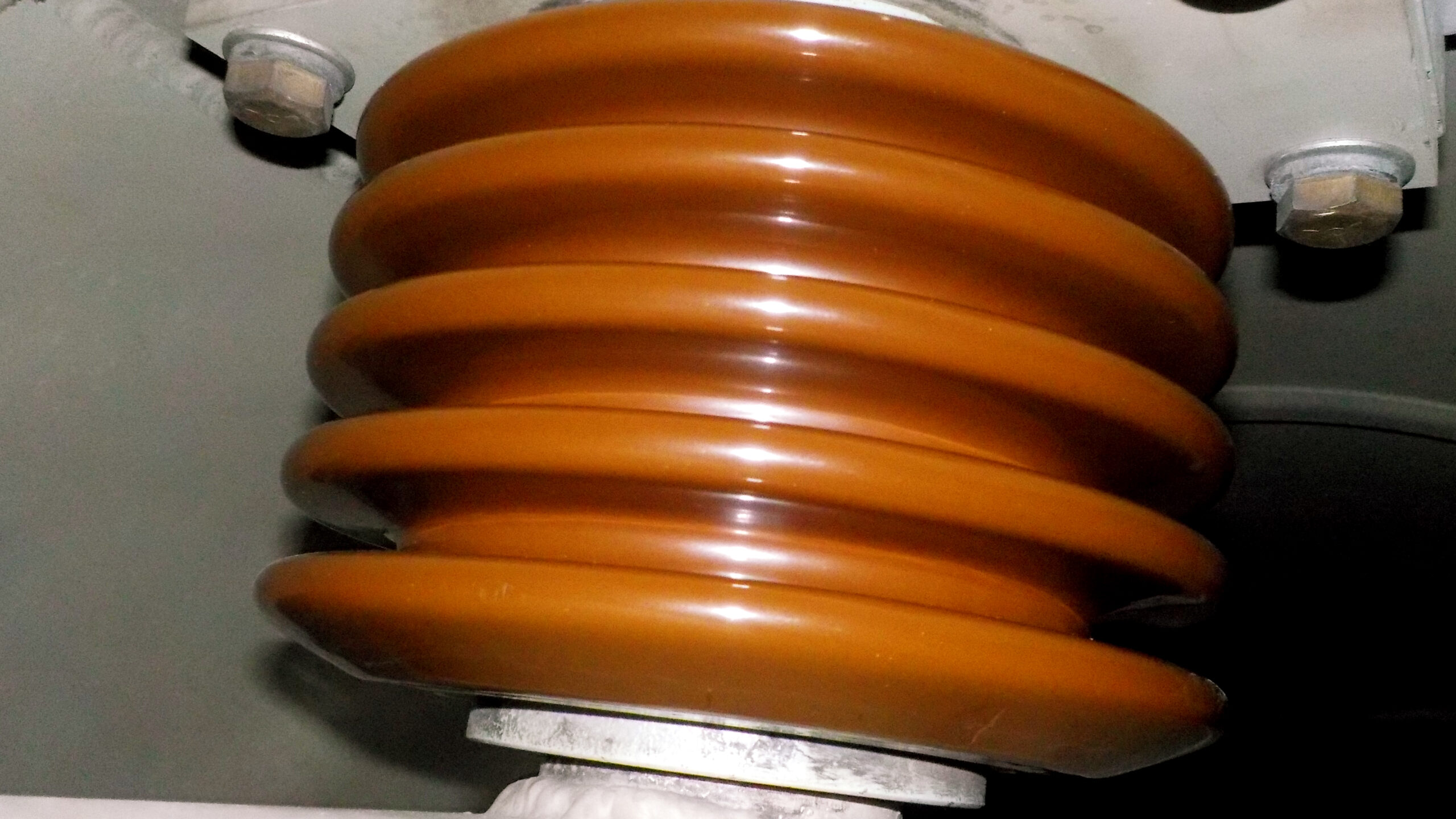

- Cracked insulators

If your electrical bus system has not been inspected by qualified personnel in the last 18-24 months, there’s a good chance that your system and its connected appendices are at risk.

Routine maintenance best practices and inspection, performed by qualified and trained personnel, are the most effective way to maintain the health of these system-critical electrical components and mitigate opportunities for a forced outage within your power generation fleet.

Environmentally friendly

Cryogenic Cleaning

EBI was the first isolated phase bus duct services contractor to develop and introduce environmentally friendly cryogenic cleaning for internal IPB components. This process cleans more than just the insulators; it thoroughly cleans inside the entire length of the bus duct system, which is where many issues hide. Cryogenic cleaning removes dirt, debris and contaminants without leaving a residue or damaging equipment.