Summary:

EBI mobilized to this coal plant on an emergency basis after the plant experienced a non-seg failure.

Scope of Work:

- Dispatched Tech Reps to inspect and assess repair needs on several components including the U5 B non-seg bus & Aux Transformer Doghouse, U7 IPB & Generator Cabinet Repairs, U7 IPB cleaning and inspection, U6 GSU Replacement, along with U6 cleaning and inspection

- Performed U5 B non-seg bus repairs

- Supply and install U5 B Aux Xfrmr of doghouse

- Supply and install of U5 B Aux Xfrmr rain shields

- Supply and install of infrared windows on the U5 B Aux Xfrmr doghouses

- Welded holes in the enclosure cover

- Supplied and installed gasket

- Resetting of the Auxiliary expansion boots

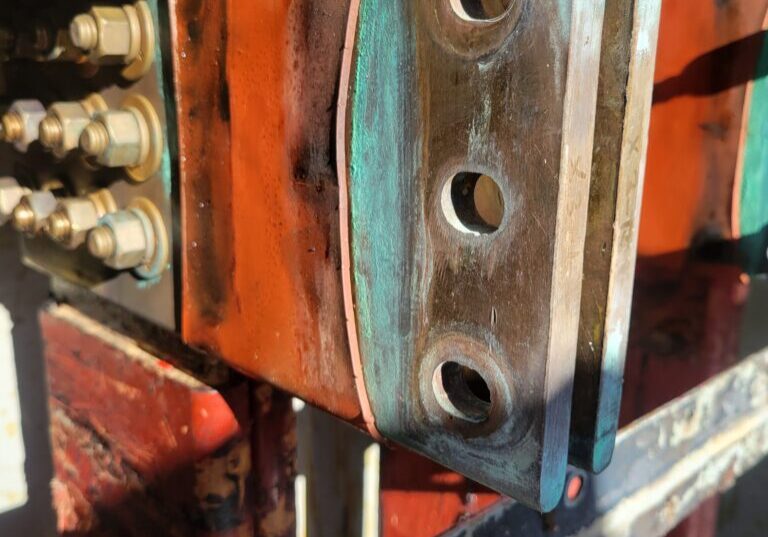

- Performed silver plating of mating surfaces on U7 IPB

- Fabrication and install of replacement de-Ionizer in U7 Gen Cab

- Performed IPB modifications for transformer change-out

- Replace the IPB termination ends on the U6 IPB at the GSU

- Fabrication and supply of new Doghouses for a replacement Xfrmr that was lower in height and a different center to center spacing than the original GSU

- Performed IPB cryogenic cleaning and inspection on both U6 & U7

Did you know that running to failure can cost up to 5 times as much as implementing a routine proactive, preventative maintenance schedule? If your non-seg bus system has not been inspected by qualified personnel in the last 18-24 months, there is a good chance that your system is at risk. Routine bus duct maintenance and inspection, by qualified and trained personnel, is the most effective way to maintain the health of these system critical electrical components and mitigate opportunities for a forced outage. In fact, 100% of clients who have relied on EBI for bus duct maintenance have avoided a forced outage! If you have an upcoming maintenance outage planned, have critical projects that require bus duct expertise, have fabrication needs, or would like to learn more about extending the life of your electrical assets, contact us today.

Project Details

| Plant Type: | Coal |

| Plant Size: | 3,653 MW |

| Plant Location: | Texas |

| EBI Job # | 2913/3052/3055/3056 |

Testimonial

"Couldn’t be more pleased with EBI. Would recommend EBI to anyone."

Drew A.

Contract Services