Summary:

During this project, EBI mobilized to perform isolated phase bus system repair, enhancements, and upgrades to provide better reliability, improve efficiency and deliver asset life extension.

Scope of Work:

- Replaced bolted shunts in horizontal expansions with bellows

- Removed old copper airline connected to bus

- Installed an air pressurization system

- Welded the shunts on PT taps, AUX 101 and AUX 102

- Removed grounding jumpers inside bus runs

- Re-gasketed the access covers inside bus runs

- Replaced the isolation on doghouse

- Replaced the steel for saddles on Main IPB outside runs

- Replaced the saddles on Main and AUX bus outside runs

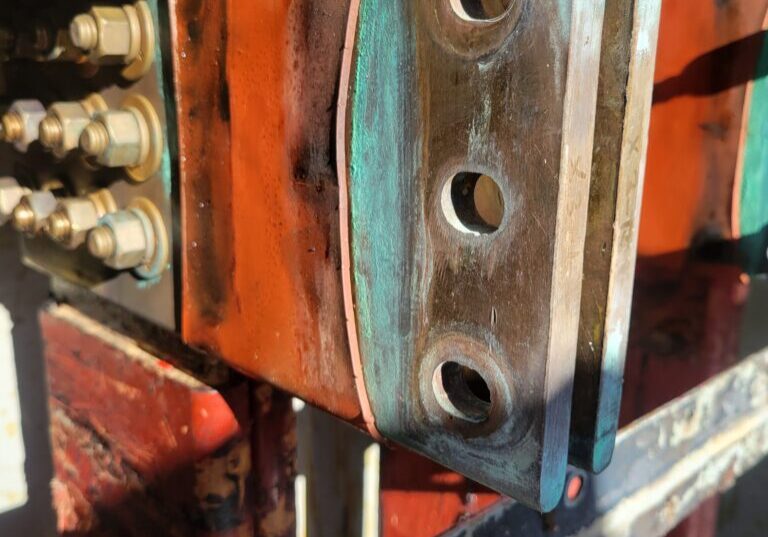

- Silver plated the GSU bushing, adapter bars, and IPB mating surfaces

- Installed adapter bars and braids at the GSU

- Completed DC Hi-Pot testing

- Modified the doghouse access door and sealed

- Provided new gasketing for AUX slide covers and top hats

EBI’s fleet wide system enhancements and improvements, coupled with preventive maintenance inspection and cryogenic cleaning, can bring your plant’s isophase and non-segregated bus duct systems back to like new condition and dramatically increased operational efficiency. If you have an upcoming maintenance outage planned, have critical transformer change-out projects that require bus duct expertise, have fabrication needs, or would like to learn more about saving time and improving your system quality with EBI’s fleet wide Maintenance & Services, give us a call at 877-297-0616.

Project Details

| Plant Type: | Coal |

| Plant Size: | 725.9 MW |

| Plant Location: | Indiana |

| EBI Job # | 3717 |

Testimonial

"Very professional at all levels. Knowledge of system, components and resolution time was exceptional. Thank you."

Derek R.

Operations Manager