Summary:

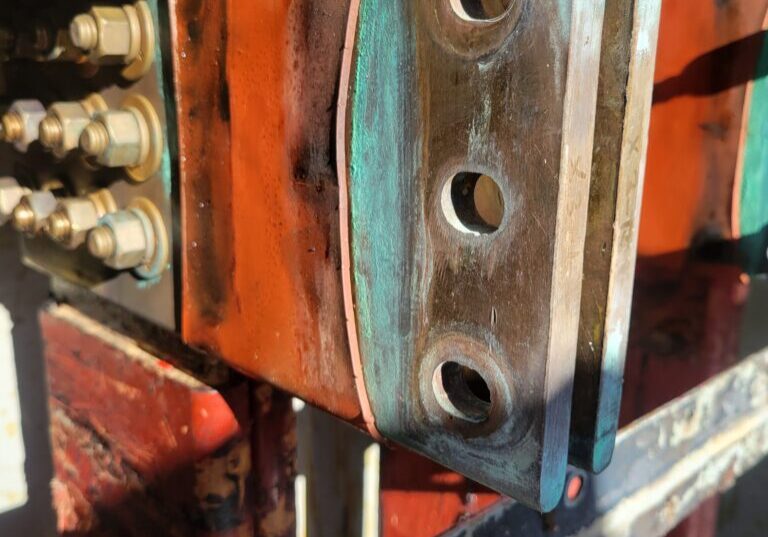

When this power plant experienced a critical bus duct failure, root cause analysis pointed to improperly torqued bolting practices and use of an incorrect joint compound. The failure caused severe damage to the enclosure, shunts, and flex links and EBI was called in on an emergent basis for needed repairs. EBI removed the damaged bolted connections, fabricated custom welded laminates and expansion bellows, and installed the new components to alleviate the reoccurring heating problems caused by incorrect maintenance practices.

Scope of Work:

- Old shunt quarter rings were cut out, new ones fabricated, plated, and welded in

- A patch was welded in to replace an area melted when the unit shorted

- Replaced two insulators that had aluminum spatter on them

- Supplied and installed new bolted cover

- Supplied additional braids and laminated shunts

- Replaced existing slide covers, shunts, and braided connections on conductor with laminates and bellow enclosure

- Fabricated rings to turn the laminates into spools and welded to existing conductor

Bolting discrepancies and lack of or incorrect maintenance practices can negatively impact plant performance and component life over time and ultimately lead to failure. EBI highly encourages utilities to consider contracting with a specialty trained and experienced bus duct services contractor, such as EBI, for all bus needs to ensure continuity and consistency of trained personnel servicing these critical electrical assets. For more information contact us at 877-297-0616.

Project Details

| Plant Type: | Nuclear |

| Plant Size: | 2,320 MW |

| Plant Location: | Illinois |

| EBI Job # | 3480/3486 |

Testimonial

"Top notch. Great crew. Understood task at hand and the urgency with it. Great information shared. Job was always top focus. Would gladly have this crew back."

Matt A.

Project Manager