Summary:

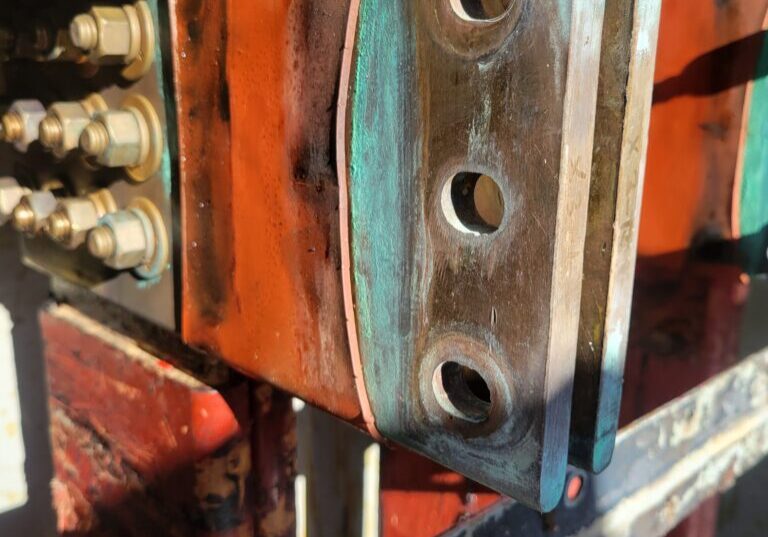

In this project spotlight we showcase the importance of having a proper assessment done by EBI’s uniquely qualified and specialty trained personnel to determine when critical contact surfaces can be re-conditioned, and when beyond repair conditions will impact the integrity of the entire system.

Scope of Work:

- Removed braids, took measurements

- Cleaned the mating surfaces

- Re-silver plated the transformer bushings and adapter bars

- Fabricated and welded in new conductor spades

- Cleaned out the doghouse

- Reinstalled new braids

- Reassembled the connections and re-gasketed the doghouse covers

- Replaced the tuck tape on the mini-bus

EBI’s refurbishment, fabrication, and repair capabilities are second to none. If you have an upcoming maintenance outage planned, have critical projects that require bus duct expertise, have fabrication needs, or would like to learn more about saving money with EBI’s fleet wide Maintenance & Service Agreement, give EBI a call at 877-297-0616 to request a proposal.

"EBI foremen did a great job of running the crews and advising us on actions that were needed for equipment reliability for the plant long term. Crews showed up on time and would communicate when they arrived, so we could engage security since they were all on visitor badges. Crew would communicate what they needed, and I did not have to continually stay with them, as I have had to do with other contractor groups. All of the work that took place was done with pride, everything that was touched was put back better than we found it. The crews took the time they needed to do it right and safely. The crews understood the procedures and processes we had in place and followed them flawlessly with little help. The crews worked very well together and were efficient in all they did. When asked with questions from the site team, they would calmly answer the questions and explain their point as to why we needed to fix what needed to be fixed. Again, your team did a great job advising us on the direction and used examples of other plants to show us why we needed to do it. It was refreshing to work with a crew who understood what it takes to work at a nuclear plant and why we had to do things the way we do. They also did not complain about anything that was asked of them. I was absolutely impressed with the work the crew did in the field. The professionalism in the field as well as in meetings was outstanding. Everyone on site was also impressed at the work the crew did and how quickly it was performed with quality. Strongest Assets: The overall understanding of how these large power systems and the guidance on how to correct the issues. The crews putting their hands on the plant. Very well trained, professional, and hard working."

Walter K. - Electrical Online Coordinator

Project Details

| Plant Type: | Nuclear |

| Plant Size: | 836 MW |

| Plant Location: | Arkansas |

| EBI Job # | 3497 |