The Growing Demand for Power – Addressing the Aging Infrastructure Crisis in Power Generation

The energy landscape is evolving at an unprecedented pace. The rise of electric vehicles, AI-driven data centers, and surging industrial power demands are pushing power generation facilities beyond their original design limits. Outdated electrical infrastructure systems—including bus ducts, transformers, and switchgear—are becoming more and more at risk of failure, leading to unplanned outages, costly repairs, and increased safety hazards. Tech giants are making massive investments in power infrastructure, but without the right expertise, these efforts risk grid instability and inefficiency. Utilities and technology leaders need a trusted partner to bridge the gap between legacy infrastructure and future demands. EBI specializes in modernizing aging electrical systems, ensuring power plants can meet growing energy needs with maximum reliability, efficiency, and safety. Our expertise in electrical infrastructure upgrades, preventative maintenance, and system longevity makes EBI an indispensable ally in securing the future of power generation.

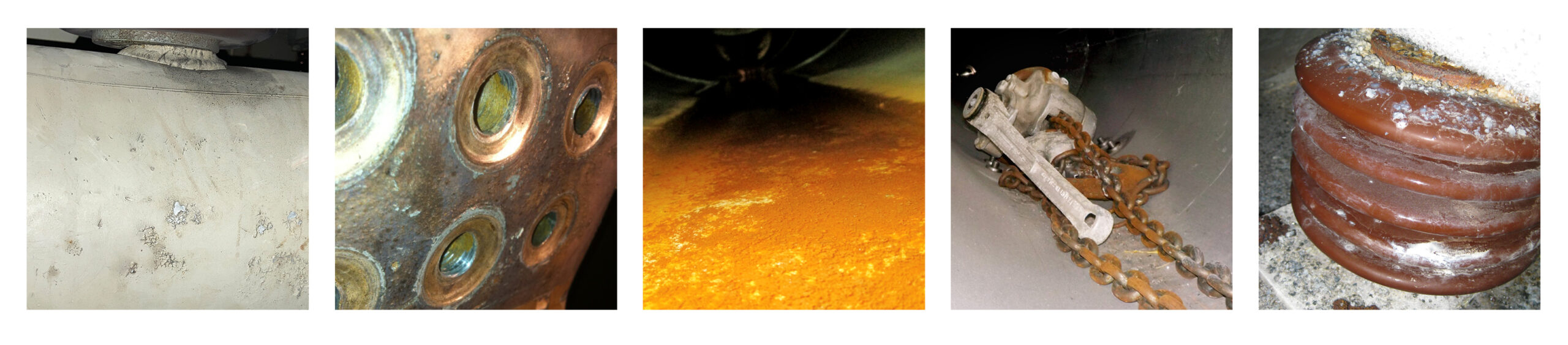

A proactive maintenance strategy begins with a comprehensive offline visual inspection of the bus duct system—identifying and addressing vulnerabilities before they escalate into costly failures. Key indicators of deterioration include:

- Corona/arcing – High-voltage discharge that leads to insulation failure.

- Loose connections – A primary cause of overheating and electrical resistance.

- Moisture infiltration – Leads to insulation breakdown and electrical tracking.

- Foreign debris and contamination – Compromises system integrity and performance.

- Deteriorated insulation – Reduces efficiency and increases failure risk.

Once vulnerabilities are detected, EBI’s targeted solutions extend asset life and optimize performance:

- Cryogenic Cleaning – EBI pioneered non-invasive cryogenic cleaning for isolated phase bus (IPB) systems, effectively removing dust and debris without damaging components.

- Dry Air Pressurization – Prevents moisture buildup inside bus ducts, reducing the risk of insulation breakdown and corrosion.

- Bus Duct Repairs & Upgrades – Strengthens infrastructure, mitigates risks, reduces maintenance costs, and ensures uninterrupted power generation.

- Asset Life Extension with System Enhancements - EBI offers aftermarket system enhancements to improve overall performance and to extend the life. Upgrades include: Dry Air Pressurization Systems, Drainage Solutions, Welded Inspection Ports, Expansion Bellows, Gasket, and Heater Solutions.

The transition to a modernized, resilient grid is already underway. Utilities and tech companies that partner with EBI can rest assured that a proactive, inspection-first approach will safeguard their operations, prevent costly failures, and ensure long-term reliability. Don’t wait for a failure to disrupt operations—act now to protect your system critical electrical assets. Contact EBI today to learn how we can keep your power systems performing at peak efficiency.