Summary:

EBI mobilized their crew and equipment to this pumped storage hydro facility to perform the removal, fit up, and weld out of 5 telescopic IPB switches.

Scope of Work:

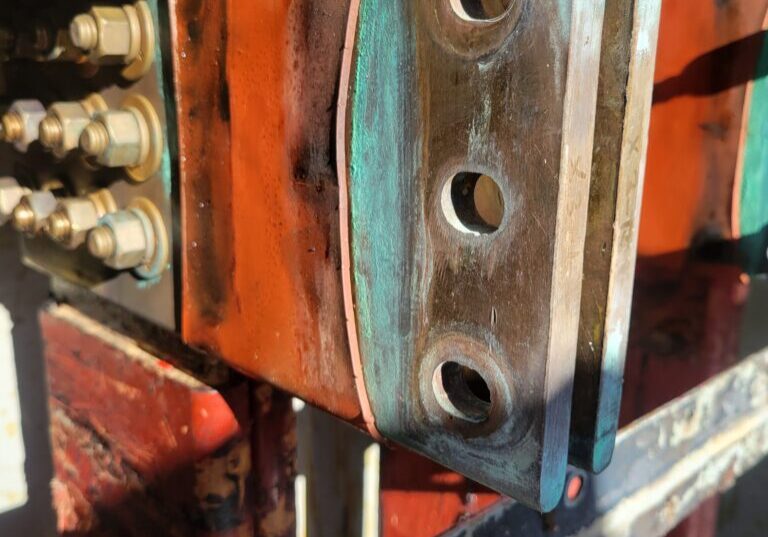

- Cut and opened the IPB enclosures on the top and bottom of 5 switches

- Cut the conductors after abatement

- Assisted with removal of the switches

- Performed final cuts on conductors and prepped for welding of new conductor

ends in multiple locations - Installed new bus adaptor in multiple locations

- Aligned new switches in place

- Took braid measurements

- Welded all new conductor ends

- Performed DC Hi-Pot test per IEEE standards and documented passed results

- Installed the braids and torqued to the proper specifications

- Welded enclosures at all locations

- Performed final FME checks and documented with photos

When planning for the outage season, it is important to keep in mind that choosing an experienced and reputable contractor plays a critical role in your outage schedule and overall project success. Selecting a contractor based on price alone without properly vetting expertise is not only risky, but the consequences can be catastrophic. Since 1974, EBI has demonstrated why we are the specialty bus duct contractor of choice for complex medium and high voltage specialty electrical system projects.

Project Details

| Plant Type: | Pumped Hydro Storage |

| Plant Size: | 1,616 MW |

| Plant Location: | Tennessee |

| EBI Job # | 3172 |

Testimonial

"Excellent work ethic."

Mike W.

Site Foreman